Updated September 2018

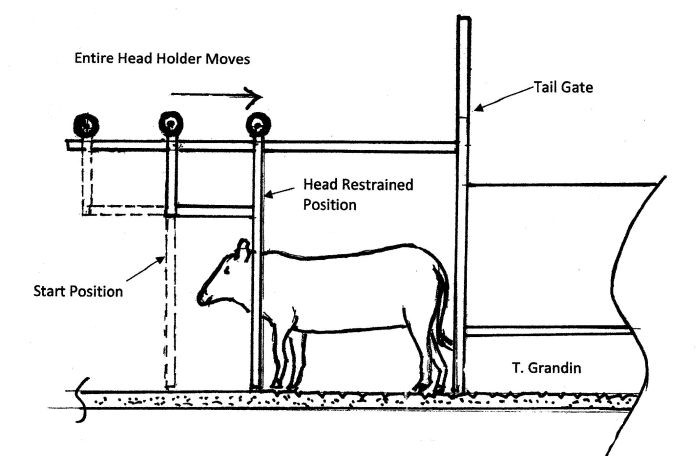

In this design, the front assembly, which has the head holder mounted on it, rolls backward towards the animal. This eliminates pushing the animal forward. When I was in the UK, I observed this design at a beef plant and it worked really well. The animal can stand still. If the entire assembly rolls backwards with a smooth, steady, slow motion, there will be very little reaction from the animal.

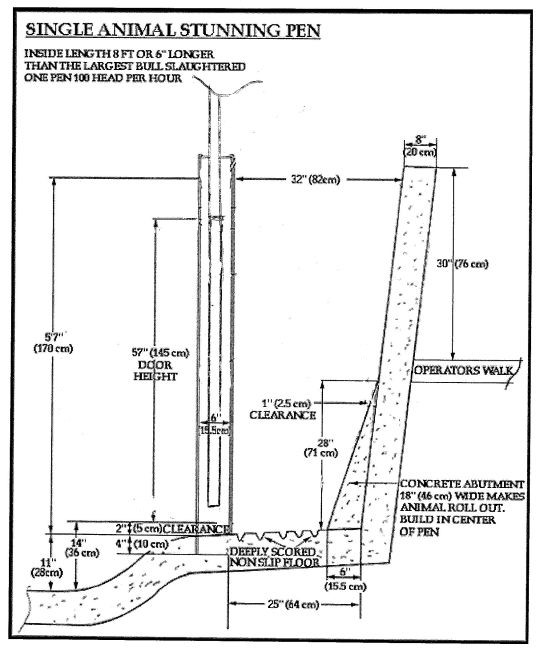

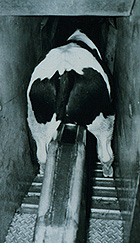

If a stunning box is used, it should be narrow enough to prevent the animal from turning around. The floor should be non-slip so the animal can stand without losing its footing. It is much easier to stun an animal that is standing quietly. Only one animal should be placed in each stunning box compartment to prevent animals from trampling on each other.

|

Image courtesy of Humane Slaughter Association |

|

Image courtesy of Humane Slaughter Association |

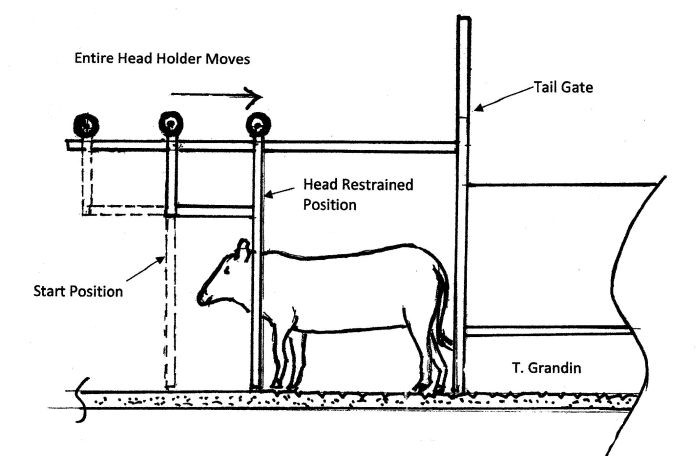

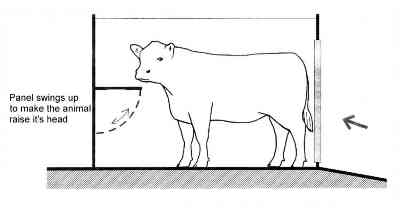

If either electric stunning or mushroom head (non-penetrating) captive bolt stunning is used a head holder like the one in this picture or similar to the headholders used for religious slaughter should be used. When non-penetrating captive bolt is used the aim must be exact. This requires holding the animal's head still.When penetrating captive bolt is used a good stunner operator may not need a headholder or one of the simpler shelf systems can be used.

In this head holder, a neck stanchion closes around the neck and a shlef is raised up under the animal's chin.

In many new plants a vertical sliding door is used instead of the rotating door to improve safety. A solid vertical sliding door can be placed in the same location as the rotating door. The angled concrete abutment can still be used to facilitate rollout of the stunned animal. When a vertical sliding door is used, there should be a 6 in (15 cm) gap at the bottom when the door is in the full down position to prevent the shackler's hands from getting caught. The stun box must have a non-slip floor. A grooved concrete floor provides better footing than steel diamond plate.

Most large plants restrain cattle in a conveyor restrainer system. There are two types of conveyor restraints, the V restrainer and the new center track system. In a V restrainer system, the cattle are held between two, angled conveyors. In the center track system the cattle ride astride a moving conveyor.

Click here to return to the Homepage for more information on animal behavior, welfare, and care.

Click here to return to the Homepage for more information on animal behavior, welfare, and care.